Corrosion & Integrity

Corrosion & Integrity

Our Solutions

To combat corrosion, various mitigation strategies can be employed, including cathodic protection, proper coating selection, and regular maintenance. These strategies aim to minimize corrosion rates and enhance the longevity of pipeline assets. Conducting thorough surveys and employing inhibitors can further contribute to effective corrosion control.

Our suit of services was designed to provide a hollistic approach to ensure critical elements of the corrosion and integrity management program are optimized for our clients.

RBI

Risk-based Inspection

At CISCAN, we provide value to Oil & Gas facilities, helping then prioritizing inspection by:

- Defining the proper RBI methodology

- Reviewing software requirements

- Creating corrosion systems

- Creating corrosion loops

- Defining piping circuit

- Understanding the risk associated with each asset

- Establishing Risk-Based inspection plans

- Reassessment

CCDs

Corrosion Control Documents

- Defining damage mechanisms

- Setting/evaluating corrosion rates

- Establishing/evaluating cracking potentials

- Creating the CCD

- Review/Auditing CCDs vs. best industry practices

IOW

IOWs are part of a proactive integrity management strategy to maintain asset safety, extending equipment life, and avoiding unplanned shutdowns. Regularly reviewed and updated based on operational changes or risk assessments, IOWs help organizations maintain safe and efficient operations.

At CISCAN, we help organizations to analyze their IOWs by:

- Defining the key process variables

- Assigning the IOW type

- Setting the IOW limits

- Ranking each IOW

- Defining mitigation actions

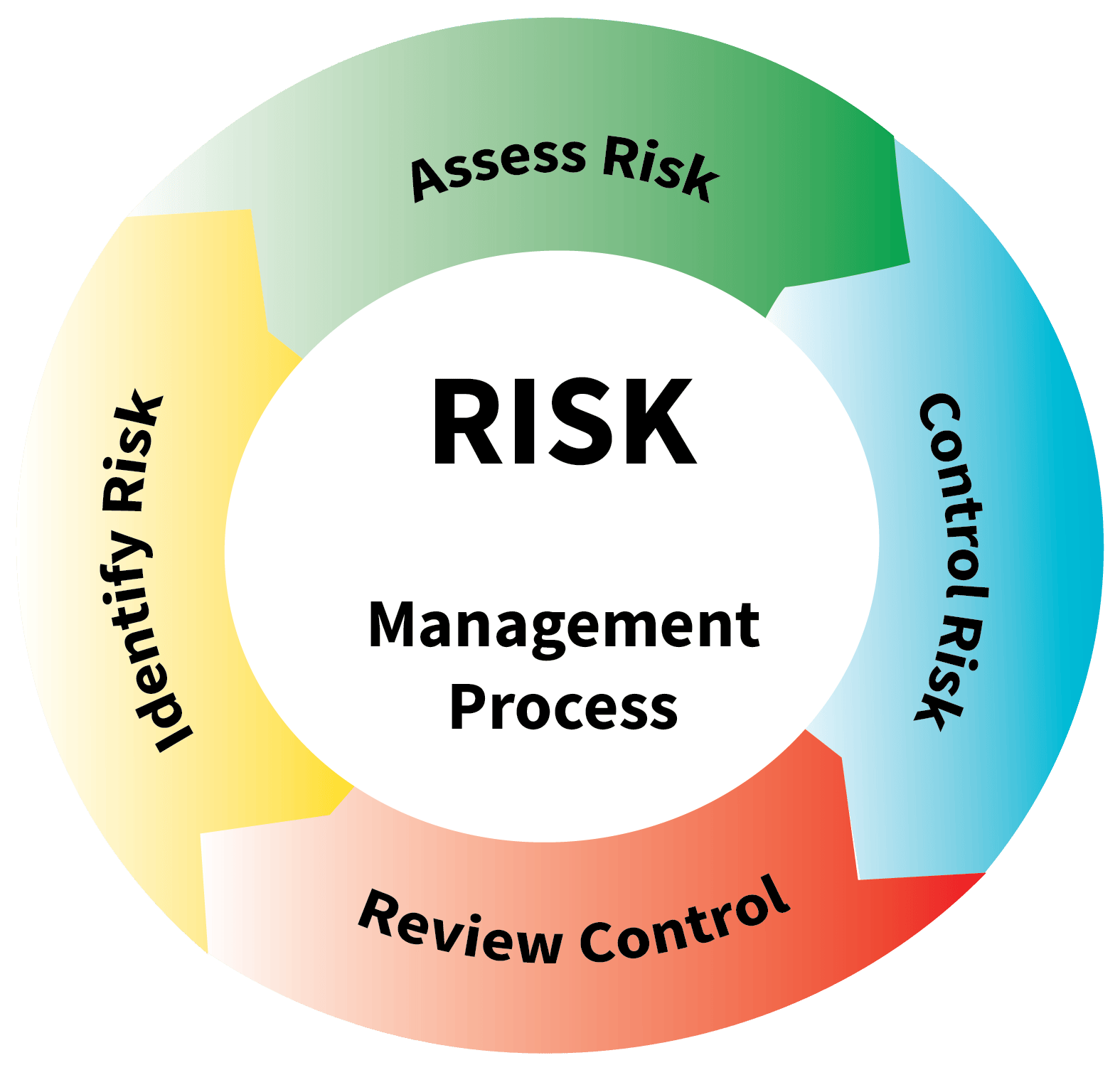

IMP

These programs incorporate systematic processes and procedures designed to manage risks and maintain compliance with industry regulations.

Our team of experts at CISCAN has extensive experience designing IMPs for your Oil & Gas assets by:

- Setting the elements of an IMP

- Establishing inspection frequencies

- Defining inspection requirements

- Auditing IMP for gaps identification and improvements

Tanks Integrity

Tanks Integrity Assessment

Storage tanks are critical process assets that require proactive inspection, monitoring, and maintenance to detect issues affecting their structural integrity, such as cracks, corrosion, or wear and tear, which could lead to leaks, spills, or contamination of stored fluids.

Investing in tank integrity not only safeguards assets but also protects the environment and ensures compliance with industry regulations, ultimately supporting long-term operational efficiency and reliability.

We offer Tanks Integrity Assessments by:

- Inspection Integrity Assessment

- Repairing Scope of Work

- Costing and Scheduling Reduction

- Complying with Regulation Standards

API Inspections

API Inspections

Effective inspection and assessment techniques are crucial for managing corrosion and ensuring the integrity of piping, pipeline systems and other static assets in the Oil and Gas industry.

Regular inspections facilitate the timely identification of corrosion mechanisms and enable proactive maintenance strategies. We offer onstream or out-of-service Inspection such as:

- API 570 Piping Inspection

- API 510 Pressure Vessel Inspection

- AP 653 Atmospheric Tank Inspection

CP

Cathodic protection (CP) systems are essential for preventing corrosion in pipeline and tank facility installations. By employing impressed current or sacrificial anodes, these systems are extensively used to protect external metal surfaces from electrochemical corrosion, and in some instances, internal corrosion of surfaces. Regular monitoring and assessment of the cathodic protection system’s effectiveness are vital to ensure that it operates optimally, providing reliable protection against external corrosion influences.

Our CP services include:

- Designing and/or Installing CP systems

- Retrofiting

- Surveying data interpretations (CIPS, DCVG, ACVG, PCM, soil test)

- Shorting Casing test

- Guiding field test selection

- Troubleshooting and inspecting

- Aligning Data

- Coating Electrical Conductance

ILI

Inline Inspection (ILI) is crucial for managing pipeline corrosion and integrity. Using advanced technologies, ILI detects and assesses corrosion, cracks, and defects, providing vital data on pipeline health. This proactive approach enables early issue detection, ensuring compliance, enhancing safety, and extending asset lifespan, while reducing the risk of failures and protecting the environment.

Our ILI services include:

- Fitness for Service (FFS) – Level 1, 2 and 3

- Running Comparison Assessments

- Evaluating Corrosion Growth Rate (CGR)

- Determining Remaining Life Assessment

- Performing Dent Assessments

- Conducting Fatigue or Free Spanning Pipelines Analytical and Numerical Assessment

ECDA/ICDA

External/Internal Corrosion Direct Assesment

External and Internal Corrosion Direct Assessment (ECDA/ICDA) are critical methodologies for identifying and managing corrosion threats in pipelines. These assessment techniques involve systematic data collection, analysis, and validation to detect areas of potential or active corrosion without the need for intrusive inspections. These methods enable targeted maintenance, regulatory compliance, and extended asset lifespan, ensuring pipeline safety and reliability

Our approach to ECDA/ICDA include:

- Pre-Assessment

- Indirect Inspection

- Direct Examination

- Post Assessment

AC Mitigation

Effective AC mitigation strategies help manage these risks by reducing AC levels to safe thresholds, thus preventing accelerated corrosion and extending the lifespan of assets and also ensures compliance with industry standards, enhances operational safety, and reduces the likelihood of unexpected failures and costly downtime.

We assist our clients with AC Mitigation strategies by:

- Simulation – AC Mitigation Modeling

- Assessment

- Design

- Troubleshooting

Corrosion Management

Corrosion Management

Effective corrosion management relies on selecting and implementing the right combination of monitoring tools, inhibitors, and protective coatings to meet the goals of integrity management programs.

Corrosion probes and coupons provide critical insights into corrosion rates within pipelines and systems, enabling operators to monitor and evaluate the effectiveness of mitigation strategies in real-time.

Equally important is the selection of biocides, scale inhibitors, and corrosion inhibitors. Biocides control microbial growth that accelerates corrosion, while scale inhibitors prevent deposits that can lead to under-deposit corrosion.

Corrosion inhibitors create a protective barrier on metal surfaces, reducing direct exposure to corrosive elements.

Coatings, as the last mechanism for corrosion protection, are vital for shielding assets from harsh environments, extending their lifespan, and ensuring operational integrity.

At CISCAN we help our clients with each of these elements of their corrosion mitigation strategies by:

- Selecting corrosion probes and coupons specification

- Selecting Biocides and corrosion inhibitors

- Determining coating specifications

Training

We offer in-house or virtual training for:

- RBI per API 580/581

- Damaging Mechanisms per API 571

- Cathodic Protection

- Fundaments of Corrosion

- Corrosion Management